Pinellas Partners in Recycling – Guidance for Developing Recycling Collection, Processing & Commodity Marketing Contracts

Overview: This guidance document is a product of the Pinellas Partners in Recycling’s Contract Work Group (WG), which develops resources to help standardize recycling collection, processing and marketing contracts through collaboration between the public and private sector. The WG’s goal is to create and maintain a resource for municipal and local governments to develop effective and fair contracts. Caveat: This guidance document is a preliminary tool to assist recycling and solid waste staff with a basic understanding of contracts. Municipalities and local governments should consult with their legal and purchasing departments regarding contracting.

Version 1.1; Published April 2023

Definitions

- Average Material Value (AMV) – the value of a load of mixed recyclables estimated by considering the individual commodity values of each Program Material in a given time period. The value can be either positive or negative depending on the quality and quantity of Program Materials, non-program materials and contamination collected and the commodity value of the Program Materials. The AMV is calculated by multiplying the percentage of each Program Material (as determined by a Composition Study) by the material’s commodity value at the time the AMV is calculated. AMV is typically calculated within a time period, such as monthly. AMV is also known as Blended Value or Monthly Market Value.

- Back-end Composition Study – a Composition Study in which the percentage composition of Program Materials is multiplied by the throughput efficiency of the Contractor’s MRF.

- Collection – pick up and transport of Recyclable Material, typically from residences or businesses, to either a Transfer Station or MRF.

- Collection Fee – a fee charged for the collection of Recyclable Material depending on frequency and location, as well as other factors.

- Commodity Index – a comprehensive, online commodity pricing index for Recovered Materials. Examples include RecyclingMarkets.net and Fastmarkets RISI.

- Commodity Marketing – the sale of Recovered Materials.

- Community – a group served by a municipal or local government recycling program.

- Composition Study –samples of Recyclable Materials from a community’s recycling program are sorted into material categories, weighed, and given a percentage of the total weight of material sampled. The study determines the composition of recyclable materials collected according to stated methodology and identifies the percentage of Program Materials vs. Non-Program Materials collected and the community’s contamination rate. The study provides a consistent baseline and measures for improvement.

- Contamination/Contaminant – non-Program material or garbage that is collected, transported, and intended to be processed. Anything other than Program Materials could be considered contamination/contaminant.

- Contaminated Recyclable Material (CRM) – Recyclable Material that is comingled or mixed with solid waste or other non-hazardous material. This definition is required to be included in solicitations per 403.706(22), Florida Statutes (see its definition below). CRM is Recyclable Material that contains some percentage of Non-Program Material. CRM can be processed so that contaminants are removed.

- Contract – an executed agreement between a Vendor and a municipality.

- Florida Statute 403.706 (22) “Local government solid waste responsibilities” – Florida Governor Ron DeSantis signed HB 73 into law on June 18, 2020, effective October 1, 2020. This law specifies requirements for contracts between residential recycling collectors or recovered materials processing facilities and counties or municipalities for the collection or processing of residential recycling material. It applies to each contract between a municipality or county and a residential recycling collector or recovered materials processing facility executed or renewed after October 1, 2020.

- Front-end Composition Study – the collected Recyclable Material that a municipality delivers to a MRF as measured by the percentage composition and weight.

- Material Recovery Facility (MRF) – also known as a Recovered Materials Processing Facility (RMPF). A facility where Recyclable Material is sorted and prepared to be marketed using a combination of human labor and equipment. A MRF must be certified as a Recovered Materials Dealer by the Florida Department of Environmental Protection in accordance with Chapter 62-722, Florida Administrative Code.

- Monthly Material Value (MMV) – see AMV definition. MMV is also known as AMV or Blended Value. If calculated monthly, AMV is MMV.

- Program Materials – Recyclable Material accepted in a community’s recycling program. In Pinellas County, Program Materials are defined here.

- Processing – the separation of Recyclable Material into separate commodities, in which contamination is removed and materials are prepared to be marketed. Processing depends on the types of materials collected. For example, if glass is collected separately, or clean cardboard is baled, processing is different from single-stream processing.

- Processing Fee – the Processing Fee is not the Vendor’s actual cost but is a fixed amount of compensation for payment by the municipality to the Vendor for its services. It is typically the price per ton the Vendor is paid to process and market Program Materials and meet the other specifications of the contract.

- Non-Program Materials – items that are not accepted in a community’s recycling program and are not defined as Program Materials.

- Piggybacking – use of another municipality’s or local government’s recycling collection, processing and commodity marketing contract(s). All terms, including price, may need to stay the same. A letter of consent may be required from both parties to honor the contract terms. Check with your purchasing department to see if this is an option as it may benefit municipalities/local governments with smaller populations and staff and lower annual Recyclable Material tonnage.

- Pre-bid meeting – a meeting held after a Solicitation is advertised and before Vendor responses are due.

- Privatization – the process of shifting the ownership or management of recycling collection, processing, and commodity marketing, in whole or part, from the government to the private sector.

- Public-Private Partnership – private sector management of a public service through a long-term contract between a private sector operator and a government could be an option.

- Recovered Materials – materials recovered from Recyclable Materials by the Vendor that have been processed and are ready for sale or distribution for beneficial use. Defined by 403.703(24), Florida Statutes as “metal, paper, glass, plastic, textile, or rubber materials that have known recycling potential, can be feasibly recycled, and have been diverted and source-separated or have been removed from the solid waste stream for sale, use, or reuse as raw materials, whether or not the materials require subsequent processing or separation from each other, but the term does not include materials destined for any use that constitutes disposal. Recovered materials as described in this subsection are not solid waste.”

- Recyclable Material (RM) – materials capable of being recycled in a community program and at a MRF.

- Residue/Residuals – the portion of Program Recyclables that are accepted by the Vendor and not converted into Recovered Materials by the Vendor due to breakage, transportation, processing limitations or inefficiencies, or because it is Contamination.

- Revenue Share – a percentage of the revenue generated by the Vendor through the sale of the Recyclable Material delivered by the municipality, which fully or partially offsets the processing fee. Revenue can be calculated based on actual sales, although most Vendors prefer calculations to be based on Market Indices. Revenue Shares are typically calculated in one of two ways:

- As a percentage of the net revenue if the AMV exceeds the processing fee. Until the AMV is greater than the Processing fee, revenue is shared with municipality at 100%. The purpose of this method is to cover the Vendor’s Processing Fee before a Revenue Share applies.

- As a percentage of all revenue generated by the commodities delivered to the Vendor.

- Solicitation – refers to a competitive advertisement for a request for response from Vendors to perform services. For the purposes of this document, a solicitation is for recycling collection, processing and/or commodity marketing service between a municipality or local government and a Vendor. Solicitations include, but are not limited to:

- Request for Bids (RFB) – also known as an Invitation to Bid (ITB). Announces and provides details about needed recycling collection and processing service and solicits prices from Vendors. The price typically dictates the award. This type of Solicitation is used when a municipality knows exactly the type of service it wanted and needed.

- Request for Information (RFI) – an organized and formal request for the information necessary to complete a purchase or fulfill a contract. An RFI can be used by a municipality to gather information about products or services that a buyer needs prior to issuing an RFP. Additionally, a Vendor can use it to get additional information about a contract.

- Request for Proposal (RFP) – a solicitation that announces and provides details about needed recycling processing service and solicits proposals, including price, from Vendors who will provide the services being requested. An RFP allows criteria to be evaluated and considered to determine the best proposal to meet the municipality’s needs. For example, the community’s goals, such as waste diversion and avoided cost of disposal.

- Request for Qualifications (RFQ) – asks potential Vendors to detail their background and experience in providing a specific good or service. An RFQ may be the first step prior to issuing an RFP.

- Vendor – Private-sector recycling collector, processor and/or commodity marketer.

Essential Contract Elements

- Determine Community Goals – before developing a contract, talk to residents, solid waste and recycling staff, elected officials, and others about your community goals. What is most important? What are needs vs. wants? For example, is it most important to the community to set and reach a diversion rate, or is it most important to provide recycling service for a simplified list of recyclable materials? If so, what are the Program Materials? Goals to consider include:

- Recovery rate of Program Materials at a MRF

- Lowest cost service

- Education/Community outreach

- Diversion rate

- Reliability in processing

- Ability to scale and grow the program to local businesses and institutions and/or neighboring municipalities.

- Minimum guaranteed tonnage – gather data on collected tons for past years, then determine the minimum tonnage of recyclable material that your community can guarantee will be delivered to the collector and/ or processor. Including this amount in the solicitation will help vendor determine whether they can accommodate tonnage and to determine their fees.

- Determine the services to include – identify the services you will include in the Solicitation and consider separating the collection from the processing to increase competition for each, as some Vendors offer only hauling or only processing. Additionally, the cost factors for each service vary (i.e., number of households served, distance driven, and fuel costs vs. volume and composition of recycling processed) as do the pricing models. If separating, consider which Solicitation should be advertised first. For example, do Vendors need to know which MRF(s) will process in order to bid on collection service? Consider what is important to processors vs. collectors. For example, processors care about timing of delivery of RM while collectors care about MRF location (i.e., distance).

- Routinely Talk to Vendors

- During Solicitation: talk to Vendors before preparing a Solicitation. Suggest issuing an RFI for a formal opportunity to talk to potential Vendors. Find out what their “deal killers” are. For example, what is their minimum Processing Fee to cover their operating costs (is it similar for majority of Vendors?), should handling of contamination be a shared responsibility and is the contract term long enough to allow for requested expenses, such as new equipment or building?

- During Contract Term: establish a protocol to regularly meet with the Vendor. Meet/talk with Vendor at least once per quarter. Talk to your Vendor about what works and what doesn’t work in your current contract.

- Evaluate the Local Market. Understand the regional/local MRF capacity and recycling commodity. How many potential Vendors are currently operating in the market? Do existing Vendors meet your business needs and Community Goals? Does the RFP need to be able to attract new Vendors to establish a presence in the community to serve the need? If a capacity study has been done, provide the results in the Solicitation.

- Contract Calendar

- Timeline: review contract expiration date and build an internal project timeline, plus award (e.g.,18-30 months prior to expiration of existing contract). Activities may include conducting a Composition Study, preparing a Solicitation with input from management/Risk and Legal department staff, advertising the Solicitation (allow extra time over the winter holiday), conduct pre-bid meeting and question/response period, response to questions, release addendum(s), add time if the proposal deadline is extended, evaluate proposals via committee if needed, negotiate the agreement, and transition Vendors, especially if contract includes collection in addition to processing. Consider that for processing contracts where the municipality would like to have the option of newly-constructed facilities, include 24 months from award date to contract start date. To allow for major equipment upgrades to existing facilities or major vehicle purchases, include 12-18 months from award date to contract start date. If acquiring land and trucks, include 18-24 months.

- Determine Contract Term: Consider the scale of the investment that will be required by the selected Vendor and set the contract term and renewal options accordingly. Longer terms may allow Vendors to offer better pricing. Municipalities can also request proposals for multiple contract term lengths to evaluate their options. For example, consider asking Vendor to give their best price for 5, 7, and 10-year terms.

- Define Program Materials and Non-Program Materials – talk to Vendor about the materials that are important to include in your recycling program.

- Define “Program Materials” and if in Pinellas County, ensure that they match the Countywide Program Recyclables Standardized List.

- Define “Non-Program Materials.” This will help maintain consistency in recycling programs in Pinellas County and will help to effectively compare proposals received.

- Consider presenting Program Materials as an appendix to the bid documents so that they can be updated during the term of the contract, as agreed upon by both parties.

- Consider identifying “Program Materials Accepted in Program” and “Program Materials Accepted but Not Promoted in Program.” For example, aluminum foil and bulky rigid plastics may be accepted in the program (and not considered Contamination), however, they are not promoted to residents as being accepted.

- Establish a collaborative process for adding or deleting Program Accepted Materials with the Vendor.

- Once Program Materials are determined, consider how they will be communicated and promoted to residents by the municipality and the Vendor. An example of a description of Program Material is below:

| Definition for Program Promotion | Definition for Commodity Markets |

| Plastic bottles and jugs (from laundry, kitchen, bath) (no caps) | PET (Baled, ¢/lb, picked up) Natural HDPE (Baled, ¢/lb, picked up) Colored HDPE (Baled, ¢/lb, picked up) |

- Recyclable Material Composition Study (“Composition Study”) – the standard operating procedure has been to have a current Composition Study to determine the percentage of Contamination and the AMV in a Contract. Be aware that MRF best practices are moving towards grading loads more frequently and as “in real time” as possible. There are some contracts moving towards tiered pricing based on the estimated contamination in individual loads. With newer robot sorters with optics, technology will be evolving to where a MRF will have relatively accurate data on the materials processed that day.

- A “front end” Composition Study is a measurement of the material percentages by weight that the municipality delivers to the MRF. This is the most common type of study.

- A “back end” Composition Study is a measurement of the effectiveness of the MRF operation (i.e., how well it recovered RM and removed contaminants). This may be a good fit for municipalities who do not want to be penalized for Program Materials in Residue (in the form of fees assessed by the processor) due to MRF operational inefficiencies or underperforming equipment and are willing to pay for this type of study (it can be expensive as it requires the MRF to process only one community’s Program’s Materials at a time). This study also may be a good fit for higher tonnage recycling collection and processing contracts that specify certain recovery rates. Contracts should specify periodic audits of the Residue in addition to audits of inbound contamination.

- Investigate the cost of a Composition Study. Determine who will pay for it and how often it will be conducted. The Composition Study should be updated regularly, annually, or bi-annually, in order to reflect changes in packaging trends or residential recycling habits.

- If proceeding with a Composition Study, identify the methodology, where it be conducted and by whom. Both the municipality and the Vendor should play a role in selecting the material sample and verifying the results. If conducted at a MRF, determine if at the front end, back end, or both ends of the processing equipment.

- Define “Contamination/Contaminant” and “Contaminated Recyclable Material”

- Include definitions of “Contamination/Contaminant” and “Contaminated Recyclable Material,” and define percentage of Contamination by volume or weight based on a recent Composition Study. See Definitions section.

- Address moisture content. Moisture in fiber (e.g., paper/cardboard) can reduce the commodity value. Excessive moisture may be considered Contamination and is more typical in commercial recycling due to open dumpster lids. It is difficult to quantify “excessive moisture.” Have a discussion with Vendor how to address excessive moisture in the Contract, who is responsible to identify, and the measures for handling excessively moist material.

- Define and establish the acceptable level of Contamination. Be familiar with your county’s and state’s contamination rate and clearly define the word “acceptable.” For example: In the countywide RM composition study report dated October 2020, Pinellas County’s recycling contamination rate, including the contents of bagged recyclables, was 18.8% by weight. This March 2020 study, which was conducted by researchers at the University of Florida (UF), found that on a historic average weight basis, the state of Florida’s contamination rate is 25% by weight. It is 27% for single-stream materials recovery facilities (MRFs) and 18% for dual-stream MRFs.

- Establish threshold levels of Contamination. Define how both parties will agree if Contamination is determined to be above threshold levels. Some options are to include the percentage of Contamination as determined by a Composition Study or agree with the Vendor on a percentage of Contamination.

- If your municipality does not have a Composition Study, consider establishing an early audit in the processing contract to set the contract on solid ground relative to Contamination and material mix (especially where revenue share is concerned). The Vendor and the community may differ in opinions as to what is comparable. The best Composition Study is a representation of what is in the community. However, if using a comparable community’s Composition Study is the only option, consider requiring the processor to propose a comparable community for your review and approval. It may be best to request a proposal of three comparable communities.

- Include a procedure for identifying and handling Contamination. New contracts should require a written process for grading inbound loads. Typically, this is a visual inspection. The contract should define the rejection process clearly (e.g., what are the roles of both parties). The Vendor should provide rejection data to the community for contract transparency and to help identify and target outreach to the routes that need it most.

- Excess Contamination: a contamination surcharge may be applied as a fee per ton added to the Processing Fee. Establish protocol for when and how the surcharge is applied. Discuss with Vendors about fees for Contamination that exceeds the threshold. For example: “Contamination at or below 20% by weight is handled as normal. If Contamination exceeds 20%, a Contamination surcharge applies.” The incentive is to collect and process cleaner materials.

- Recovery Rates and Incentives – consider specifying minimum recovery rates for Program Materials. The purpose of establishing recovery rates is to assess the percentage of Program Materials that end up in Residue.

- Establish how the Vendor will be held accountable for attaining the recovery rates; options are to establish a capture rate of all Program Materials vs. Residue. For example, if establishing recovery rate by Residue: “the Contractor guarantees that the Contaminants, Rejects, and Residue output from processing Program Materials shall contain less than 10% by weight of Program Materials.” In this case, the recovery rate is determined via a Back-end Composition Study in which the Vendor chooses random sample from your routes, sets the material aside, then runs only your Program Material through the MRF and weighs the Program Materials vs. Residue to see if Residue contains less than 10% Program Materials.

- Considering that the back-end study is time-consuming for the MRF, a back-end Composition Study one or two times per year is reasonable. Specify who will pay for it. Consider option to slow processing down to increase recovery, particularly during rainy season. Account for moisture on day of study (don’t have same expectations for dry season).

- Each community will have different goals in terms of balancing cost vs. recovery targets. Performance standards should be fully considered before issuing the RFP, knowing the cost will go up with more materials being targeted and higher performance goals. Also, specify how performance goals will be measured and enforced and what penalties occur when they are not met. We recommend specifying in the Solicitation that sending RM to Waste-to-Energy is not an option as a “recycling processor.”

- Recovery Incentives – discuss the speed of processing needed for recovery targets and the equipment/technology to increase recovery of specified materials. Consider allowing the Vendor to decide speed of processing and not specify. Although a Program Material may have minimal or negative market value, it still may be cost-effective to recover compared to the cost to dispose if removed from the list of Program Materials.

- Processing Fee – It should be clearly stated in the Solicitation the services included in the Processing Fee. The fee typically includes Vendor’s profit. The Processing Fee may depend upon other factors, such as whether transfer costs are needed, how Residue and Rejects are accounted for, the community’s contamination rate, revenue share calculations, etc.

- Revenue Share and AMV – Including a Revenue Share and AMV in the Solicitation has potential to allow Vendor and municipality to share risk for fluctuating commodity market values.

- Developing AMV Calculation and Revenue Share: There are a variety of options. Ask other municipalities about their calculation. Consider hiring a consultant to develop for your community. Be aware that Contamination has a zero-dollar value in most AMV calculations; however, a negative dollar value is currently being attributed to Contamination to help recuperate the cost of rejections and disposal.

- Frequency of Calculation. Determine how often the AMV will be calculated. AMV can be calculated monthly, quarterly, etc. Monthly is most common. Specify which Market Index will be used and the date in the month in which AMV will be calculated. For example, use the first value entered in the month. The AMV will shift not only based on the market values but on the composition of the stream. How often a composition study is conducted will impact the AMV during the contract term. See section on Composition Studies.

- Who will calculate? Either the Vendor or the municipality can calculate. Alternatively, the Vendor can calculate, and the municipality can verify.

- Examples of Revenue Share: Separating the Processing fee and Revenue Share is the norm and to deviate from this may mean few to no bids. Vendors can propose a Revenue Share with their Processing Fee proposal. Revenue Shares are typically calculated in one of two ways:

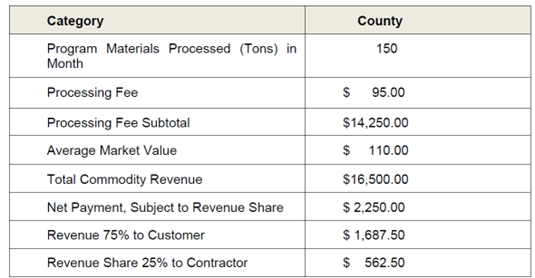

- Example 1: As a percentage of the net revenue if the AMV exceeds the Processing Fee. In this example the Processing Fee is deducted from the Commodity Revenue; the Municipality and Vendor share in the revenue by splitting the remaining $2,250.

- 150 tons Program Materials tons delivered to MRF

- $95.00 Processing fee per ton

- $110 AMV per ton

- Example 1: As a percentage of the net revenue if the AMV exceeds the Processing Fee. In this example the Processing Fee is deducted from the Commodity Revenue; the Municipality and Vendor share in the revenue by splitting the remaining $2,250.

- Example 2: As a percentage of all revenue generated by the commodities delivered to the processor.

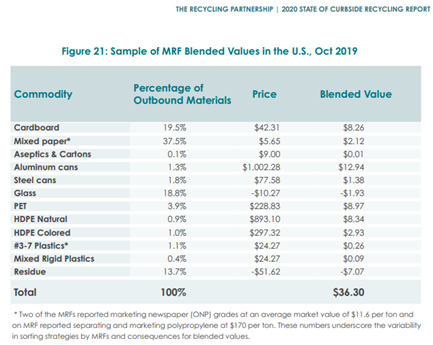

- Example AMV Calculation: in the example below, the percentage of materials is multiplied by the commodity price, then added to create AMV (or Blended Value), which is $36.30 per ton in the example below.

- Market Index – the AMV is determined using a subscription service, such as Fastmarkets RISI or RecyclingMarkets.net, which includes SecondaryMaterialsPricing.com (glass, metal, plastic) or SecondaryFiberPricing.com (cardboard, paper). Include the region, and whether the low, average or high price will be used. In the event that Fastmarkets RISI or SecondaryMaterialsPricing.com or SecondaryFiberPricing.com no longer post or otherwise provide the applicable market indices, consider stating that you and the Vendor will agree upon a replacement index and execute an appropriate amendment to the contract specifying the replacement index to be used in the monthly revenue adjustment calculations.

- Evaluating pricing proposals – because the pricing model of a Processing Fee and Revenue Share may make it challenging to compare “apples-to-apples” in terms of ultimate financial impact to a community, municipalities can use historical price information from Market Indices to evaluate various Processing Fee/Revenue Share proposals in different market conditions: strong markets, down markets, and an average market price over time. Some municipalities don’t have access to commodity pricing. Consider requesting the historical, average AMV for Program Materials from the Vendor in their response (note that this doesn’t account for changing material stream). Alternatively, if the municipality needs help with markets, contact Pinellas County Solid Waste for assistance.

- Processing Fee – consider allowing Vendor to “fill in” the Processing Fee in the RFP. Ask for separate quote for single-stream processing and source-separated “dump and bale” processing.

- Collection Fee – consider adding a separate line item for collection, which allows both parties to see true cost of collection vs. processing. Ask for separate quotes for curbside pickups, transfer station hauls, and/or drop-off station pick-ups. Note that the frequency of pickups, equipment/vehicles needed, and routing will affect the Processing Fee.

- Public Education – there is a cost associated with public education for recycling programs; be specific about what you want the Vendor to do. For example, ask the Vendor for suggestions of ways to educate together and for samples of educational programs, handouts, and labels.

- If asking Vendor to contribute to public education, the bid document should set expectations, as in “We expect two mailings per year, brochures, cart labels for 70,000 homes, and assistance with our website.” This will help Vendor prepare a response.

- Note that the educational component will be different for collection contracts than for processing/marketing contracts. For example, if the Vendor is only the processor, the Vendor’s role is to work with the municipality because there’s no direct link to the customer.

- Identify in the Solicitation the municipal educational resources that are already produced and distributed to satisfy 403.706(22), Florida Statutes, which requires municipalities and contractors to describe how they will reduce contamination. For example, use existing resources, such as:

- Pinellas County Solid Waste (SW) annual Recycle Guide.

- SW’s Where Does It Go? Search Tool – For Homes and For Businesses (this tool is available to either link or embed the code on municipal websites).

- The regional recycling campaign “Tampa Bay Recycles” has campaign collateral to promote reduction of Contamination, such as plastic bags. Municipal logos can be applied on this landing page at no cost.

- Recycle Across America label artwork for curbside and drop off recycling and garbage collection containers is available to municipalities at no cost (there is a cost for printing the labels). Pinellas County Solid Waste has a licensing agreement with Recycle Across America for artwork and printing of standardized recycling and garbage container labels. Contact recycle@pinellas.gov for information about the labels.

- Enforcement – for collection contracts, ask Vendor for suggestions of ways to enforce together. Enforcement consists of having either municipal staff or Vendor’s staff check carts at the curb (i.e., involves labor). Evaluate grant opportunities or interns for an enforcement program. The goal of an enforcement program is to provide concise and consistent messaging to residents and to gain compliance with recycling program rules. Ask regional and local partners for examples of enforcement initiatives (e.g., SWANA Forum). If the contract is going to include collection, it could be worth including how contaminated carts will be handled if rejected.

- Cart/Containers – in the Solicitation, describe your collection program and what you expect (i.e., frequency of service, types of trucks, the types of carts expected, warranty length and who will provide and maintain the container). If the municipality purchases carts, cost will be tax-free and municipality keeps the carts. Consider identifying Program Materials and contact information on recycling collection containers. Program Materials can be identified using a hot stamp or labels. Be cautious about placing labels as program materials may change. Hot stamp fades in the Florida sun and labels peel and become litter. Alternatively, a QR code to municipality’s website can be hot stamped (information can be easily updated).

- Cart Colors – vendors will often leave cart colors up to municipal governments. While cart colors are not standardized by federal or state law or by County ordinance, to reduce customer confusion, for new collection contracts, consider using black/grey carts for garbage, blue carts for recycling, and green for organics/yard waste.

- MRF Site Visits – at least one to two times a year, visit your MRF, observe operations, and ask questions. Include your solid waste and recycling staff, contract manager, and/or public/elected officials in the visits. At least once per year, ask Vendor to complete The Recycling Partnership’s MRF Survey.

- MRF Tours – the contract should specify if public tours are allowed, how often, what size of groups, and how much notice should be provided to the MRF.

- Force Majeure Event – consider including a provision in Solicitation to handle unforeseen events and define what does and does not constitute Force Majeure.

- Contingency Plan for Continuity of Operations – covers any type of interrupted service, including upgrades/retrofits. Provide process for how service will continue during disruption. State the goal is to recycle as much material as possible. Address collection and delivery to a different location, and who will pay to haul RM to another facility. You should either have a plan or state that Vendor will provide a plan at the beginning of the contract.

- MRF Technology – consider including ongoing investments in upgrades and retrofits as evaluation criteria in the Solicitation and include or require plans for processing material while a facility is down for major upgrades and retrofits. Be aware that as you enter a new contract, technology is changing and moving toward artificial intelligence and advanced learning technology (i.e., robots).

- Price adjustment – relating price adjustment to Market Indices ensures that increases under the Contract have a basis. For example, if fuel prices are increasing drastically, then an appropriate index—such as the Consumer Price Index—will reflect this change. The contract may include an option to price adjust at some frequency (i.e., annually) during contract term. Alternatively, you can request pricing for each year of the contract and exclude a price adjustment. State who can request (i.e., Vendor must request it), the process for requesting, at what point the index will be applied, and the date that the adjustment begins. Determine the Market Index upon which the price adjustment is based. An example of an index description is “Consumer Price Index (CPI) or 3%, whichever is less, for all Garbage and Trash Collection, Urban Consumers, Series Id: CUUR0000SEHG02, Not Seasonally Adjusted, Area: U.S. city average, Item: All items, Base Period: 1982-84=10.” Consider including a provision to petition for extraordinary increase.

- Hold a “Pre-Bid” meeting – a pre-bid meeting is an opportunity for the municipality to clarify the scope, provide guidance to potential Vendors about expectations, and receive Vendor input. Pre-bid meeting options are “mandatory,” “non-mandatory,” or “no meeting.” Understand ramifications of each option. For example, if “mandatory” and Vendor does not appear at meeting, their proposal may not be considered. It is recommended to hold at least a non-mandatory pre-bid meeting as it provides insight into the questions that Vendors have and the written questions that Vendors may submit during the Q&A period. Note that the meeting may be attended by more than one Vendor and may not be the most advantageous venue for open discussion. Suggest talking to Vendors before developing an RFP via an RFI.

Takeaways

- Prior to developing a Solicitation:

- Talk to residents, public/elected officials, and others about your community goals. What is most important? What are needs vs. wants?

- Talk to your Vendor, other Vendors, and other municipalities and local governments about what works and doesn’t work in a contract. The goal is to receive responses to your Solicitation that meet your community’s needs.

- Pinellas County is a partner to its municipalities and regional governments and is willing and able to provide support. The County stands by to offer resources before, during, and after a contract is in place.

Resources

- Federal:

- Non-governmental:

- The Recycling Partnership’s:

- Solid Waste Association of North America (SWANA) & National Waste and Recycling Association (NWRA)’s “Joint Advisory on Designing Contracts for Processing of Municipal Recyclables,” amended August 1, 2018. (use internet search).

- SWANA’s Open Forum

- In the Public Interests’ (ITPI’s) “Best Management Practices in Municipal Waste Contracting,” November 2016 (use internet search).

- State:

- Local:

- Pinellas County Solid Waste’s 30-year Solid Waste Master Plan

- Pinellas Partners in Recycling:

- Contract Work Group Resources

- Charter

- Contract Guidance Document (November 2020)

- References

- Countywide Program Recyclables: Standardized List

- Pinellas County Recycling Market Analysis

- Pinellas County Recyclable Material Commodity Forecast, Issues, Trends, and Access (FITA) dated July 22, 2020

- Pinellas County Solid Waste Technical Management Committee

- (To be developed) Highlights from three to five examples of regional recycling collection, processing, and commodity marketing contracts (i.e., procedures for identifying contamination, complying with 403.706(22) F.S., piggybacked contracts, etc.). For copies, contact recycle@pinellas.gov

- Contract Work Group Resources